Polyester is one of the most widely used synthetic polymers in the world, recognized for its versatility and performance in various industries, from fashion and home textiles to automotive and industrial applications. Among the different types of polyester, virgin polyester—produced directly from petrochemical feedstocks rather than recycled materials—offers superior mechanical properties due to its unaltered molecular structure. This article delves into the mechanical attributes of virgin polyester, focusing on its strength, durability, and resilience, while also examining its performance in practical applications.

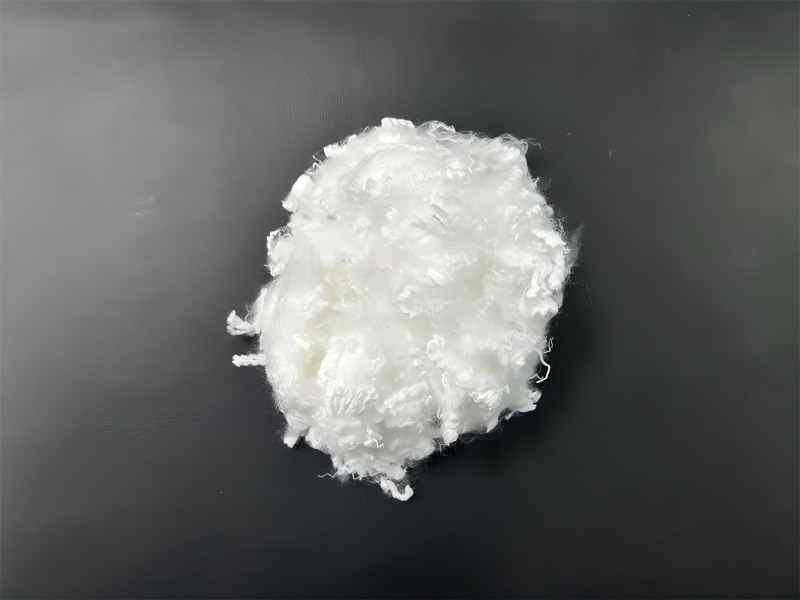

What Is Virgin Polyester?

Virgin polyester, the purest, unprocessed form of polyethylene terephthalate (PET), is made by polymerizing pure terephthalic acid (PTA) with monoethylene glycol (MEG). Unlike recycled polyester (rPET), virgin polyester has not undergone any degradation, contamination, or molecular chain scission due to previous use or heat processing. This allows virgin polyester to retain the full integrity of its mechanical properties, which are critical in applications requiring high performance and reliability.

Tensile Strength: A Key Indicator of Mechanical Performance

The highest stress a material can bear when stretched before breaking is known as its tensile strength. For virgin polyester, this property is one of its most impressive attributes.

Properties:

- High Tensile Strength: Virgin polyester fibers have a tensile strength ranging from 4.0 to 9.5 grams per denier, depending on the draw ratio and fiber processing.

- Molecular Orientation: The alignment of polymer chains during fiber spinning enhances their ability to withstand stretching forces.

- Applications: Ideal for seat belts, ropes, tire cords, and high-strength fabrics.

- In comparison, recycled polyester may show slight reductions in tensile strength due to shorter molecular chains and thermal degradation during reprocessing.

Durability: Resistance to Wear, Fatigue, and Aging

Virgin polyester is renowned for its long-term durability, especially under physical stress, environmental exposure, and repetitive motion.

Abrasion Resistance:

- Virgin polyester exhibits excellent abrasion resistance due to its crystalline structure and surface hardness.

- Suitable for upholstery, outdoor gear, and industrial belts.

Fatigue Resistance:

- Maintains integrity even after repeated loading and unloading cycles.

- Useful in applications like conveyor belts, seat cushions, and flexible composites.

Environmental Durability:

- UV Resistance: When stabilized with additives, virgin polyester resists degradation from UV exposure, making it useful for outdoor and marine applications.

- Chemical Resistance: It can withstand the majority of acids, solvents, and oxidizing agents.

Comparison Table: Virgin vs Recycled Polyester in Durability

| Property | Virgin Polyester | Recycled Polyester |

| Abrasion Resistance | Excellent | Moderate to Good |

| Fatigue Resistance | High | Medium |

| UV Stability (with Add.) | High | Variable |

| Resistance to Aging | Excellent | Decreased with cycles |

Resilience: Shape Retention and Recovery

Resilience refers to a material’s ability to bounce back after deformation. This is especially crucial for molded plastic components, cushions, and textiles.

Elastic Recovery:

- Virgin polyester fibers recover quickly after stretching or compression.

- Maintains wrinkle resistance and shape in clothing and furnishings.

Creep Resistance:

- Virgin polyester shows low creep under constant stress, meaning it doesn’t stretch out permanently over time.

- Essential for applications like sails, tent fabrics, and geotextiles.

Moisture and Thermal Resilience:

- Polyester absorbs less than 0.4% of its weight in water, contributing to quick-drying properties and structural stability.

- Maintains its mechanical strength even at temperatures between -70°C and 170°C.

Comparative Mechanical Data of Virgin Polyester

Here are the key mechanical parameters of virgin PET:

| Mechanical Property | Value Range |

| Tensile Strength | 55–85 MPa |

| Tensile Modulus | 2.5–4.0 GPa |

| Elongation at Break | 15–30% |

| Impact Strength | 20–30 J/m |

| Hardness (Shore D) | 80–85 |

| Density | 1.38 g/cm³ |

| Moisture Absorption | < 0.4% |

| Thermal Stability | Up to 170°C |

Strength and Performance in Fabric Form

When virgin polyester is spun into yarn and woven into fabric, its mechanical advantages multiply:

- High tear strength, reducing fabric damage under tension.

- Dimensional stability helps garments maintain fit and form.

- Pilling resistance, thanks to the tight molecular bond and smooth fiber surface.

These attributes are critical in producing sportswear, industrial uniforms, backpacks, and parachutes.

Role in Composite Materials

In composite form—when virgin polyester is combined with reinforcements such as fiberglass or carbon fiber—it contributes to:

- Improved load distribution

- High-impact resistance

- Cost-effective strength-to-weight ratio

This makes it a viable matrix material for automotive panels, electrical insulation, and structural reinforcements.

Sustainability Considerations

While virgin polyester is mechanically superior to recycled alternatives, it comes with environmental trade-offs:

- Derived from non-renewable petroleum sources.

- Requires significant energy input for polymerization and fiber production.

- Not biodegradable, but fully recyclable under closed-loop systems.

Balancing environmental impact with performance is vital, and virgin polyester is used in high-performance applications requiring exceptional strength and durability.

Limitations of Virgin Polyester

Despite its strengths, virgin polyester has some limitations:

- Low moisture permeability: Can feel less breathable than natural fibers.

- Use in high-temperature situations is limited by its low melting point of about 250°C.

- Static build-up: Requires anti-static treatments in certain textile applications.

- Environmental footprint: Not suitable for brands prioritizing biodegradable or circular materials.

However, for load-bearing, wear-resistant, and precision applications, virgin polyester remains unmatched in synthetic fiber classes.

Key Applications That Rely on Virgin Polyester’s Mechanical Strength

Here are a few industries and products that capitalize on the mechanical performance of virgin polyester:

Textiles & Apparel:

- Sportswear, jackets, outdoor fabrics, military clothing

- Blends with cotton for wrinkle-free garments

Industrial:

- Conveyor belts, tire cords, and safety harnesses

- High-strength threads and ropes

Automotive:

- Seat belts, airbags, and interior trims

- Hoods and panels made of composite materials

Packaging:

- PET food and drink containers, films, and bottles

- Blister packs and vacuum-formed products

Construction:

- Geotextiles for soil stabilization

- Insulating foams and structural panels

These sectors prioritize long-term integrity, stress resistance, and cost efficiency, making virgin polyester indispensable.

Research and Development Trends

Innovation around virgin polyester is focused on:

- Variants with high tenacity: Providing even more tensile strength and resistance to tearing.

- Surface-modified fibers: Improving moisture management and dye uptake.

- Bio-based virgin polyester: Derived from renewable monomers, merging strength with sustainability.

- Nano-composites: Incorporating nanomaterials to enhance flame resistance and mechanical behavior.

R&D is working to preserve the mechanical advantages of virgin polyester while addressing its environmental concerns.

Conclusion

Virgin polyester stands out for its exceptional mechanical properties, including high tensile strength, remarkable durability, and impressive resilience. These characteristics are the result of a stable molecular structure, which enables the material to perform under demanding conditions across numerous industries. While environmental considerations may prompt the growing use of recycled alternatives, virgin polyester remains essential where mechanical performance cannot be compromised.

As innovation continues, the challenge lies in merging the mechanical superiority of virgin polyester with the sustainability goals of modern production. For now, virgin polyester continues to power industries with reliable strength, long-lasting durability, and resilient adaptability.