Thermal bonding is a key method in textile and nonwoven manufacturing, offering strength, flexibility, and eco-efficiency. Low-Melt Polyester Fiber (LMPF), designed to melt at low temperatures, enhances this process by bonding with other fibers under heat, creating cohesive, high-performance materials.

Understanding Thermal Bonding in Fiber Networks

Thermal bonding is a process used to bind fibers together through the application of heat, without the need for chemical binders or solvents. Unlike mechanical entanglement or needle punching, thermal bonding relies on the melting and resolidification of a bonding agent within the fiber web.

There are several methods used to achieve thermal bonding:

- Calendar bonding (passing the web through heated rollers)

- Air-through bonding (hot air penetrates the fiber matrix)

- Infrared bonding

- Ultrasonic bonding

The type of material, intended usage, and desired fabric properties are taken into consideration when selecting each process. Regardless of the technique, thermal bonding is only effective if at least some component fibers can soften or melt at processing temperatures—this is where LMPF enters the picture.

What Is Low-Melt Polyester Fiber (LMPF)?

Low-melt polyester fiber is a bicomponent or modified homopolymer fiber engineered to melt or soften at a temperature significantly lower than standard polyester fibers.

Typical LMPF types:

- Sheath-core bicomponent fibers: LMPF forms the outer sheath, and a high-melting-point polyester forms the core.

- Side-by-side fibers: LMPF is integrated along one side of the fiber strand.

- Single-component low-melt PET: Modified to have a lower softening point without dual layers.

Common melting points:

- LMPF sheath: 110°C to 180°C

- Standard PET fiber: 255°C to 265°C

This differential in melting temperatures allows LMPF to melt and flow, while the high-melt component maintains structure. Upon cooling, the molten LMPF solidifies into a binder, locking adjacent fibers into place.

The Science of Fiber Interlocking Through LMPF

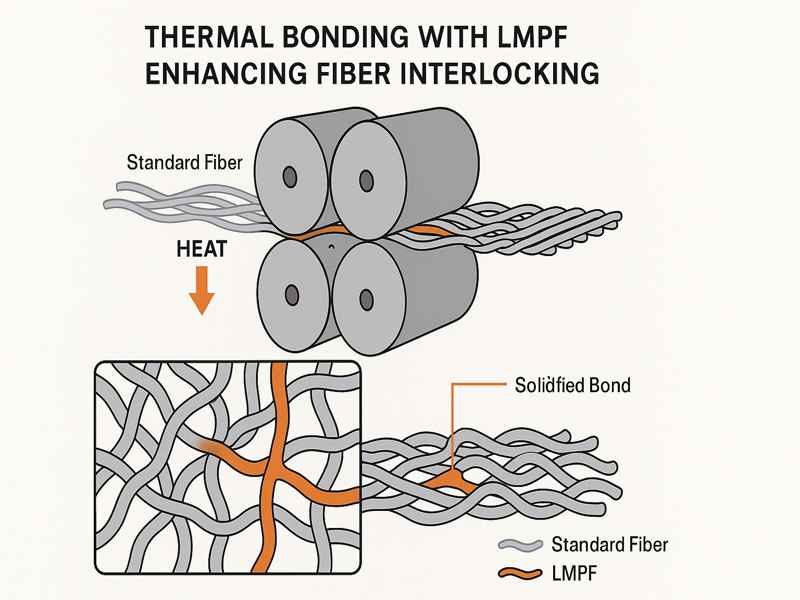

The primary role of LMPF in thermal bonding is to act as a thermal adhesive. Let’s break down how this process enhances fiber interlocking:

A. Surface Wetting and Adhesion

When heat is applied, LMPF’s sheath melts and begins to flow across the surface of neighboring fibers. This process is called wetting, which allows for maximum contact area. The molten sheath wraps partially or fully around adjacent fibers, increasing surface adhesion.

B. Molecular Diffusion at Contact Points

At elevated temperatures, polymer chains from the molten LMPF and those of adjacent fibers can begin to interdiffuse. This chain entanglement forms physical bonds at the molecular level, further enhancing the mechanical strength of the network.

C. Cooling and Solidification

After the thermal treatment, the structure is cooled. The molten LMPF solidifies into rigid inter-fiber joints, effectively converting a loose web into a cohesive and strong nonwoven fabric.

Factors That Influence Bond Strength and Efficiency

The performance of thermal bonding using LMPF is influenced by several key factors:

| Factor | Impact |

| LMPF Content (%) | Higher content increases bonding points but may reduce fabric softness or flexibility. |

| Temperature | Needs to be above LMPF melting point but below the degradation point of other fibers. |

| Dwell Time | Sufficient time is required to allow melting, wetting, and diffusion. |

| Pressure (in calendaring) | Enhances contact between fibers, improving heat transfer and bond quality. |

| Fiber Denier | Finer fibers have more contact points, enhancing interlocking density. |

| Blending Method | Uniform dispersion of LMPF throughout the web results in consistent bonding. |

Advantages of Using LMPF for Fiber Bonding

Using LMPF in thermal bonding provides numerous benefits over traditional chemical or mechanical bonding:

- Binder-free construction: No need for added adhesives or binders, reducing chemical residues.

- Recyclability: Homogeneous fiber types (e.g., 100% polyester blends) are easier to recycle.

- Breathability: Maintains porosity and air permeability.

- Customization: Bonding strength, softness, and stiffness can be controlled via fiber composition and processing parameters.

- Eco-friendliness: Lower energy requirements and reduced emissions compared to chemical curing.

Applications Enhanced by LMPF-Based Bonding

Thermally bonded materials with LMPF have gained widespread use in:

A. Automotive Interiors

Used in headliners, door panels, and seat padding. The strong yet lightweight structure achieved with LMPF bonding ensures dimensional stability and comfort.

B. Filtration Media

Air and liquid filters benefit from the open yet stable structure of thermally bonded nonwovens, providing excellent flow rates and filtration efficiency.

C. Hygiene and Medical Products

Diapers, sanitary pads, and surgical masks require soft, absorbent, and durable layers. LMPF enhances bonding without compromising softness or breathability.

D. Insulation and Padding

In thermal and acoustic insulation, LMPF-bonded mats maintain loft and integrity even under pressure or over time.

E. Furniture and Bedding

Mattresses, pillows, and cushion fillers benefit from consistent structure and hypoallergenic properties of LMPF-bonded polyester fillings.

Recent Innovations in LMPF Technology

The development of new LMPF types and bonding strategies continues to evolve:

- PLA-based LMPF: Biodegradable options now available to support sustainable production.

- Multicomponent fibers: Advanced designs offering multi-stage melting behavior for complex applications.

- Nanofiber bonding: LMPF used in conjunction with nanofiber webs to stabilize ultra-fine structures.

These innovations are not only improving performance but are also helping manufacturers align with circular economy and zero-waste goals.

Comparing LMPF Bonding vs. Other Bonding Techniques

| Bonding Method | Main Bonding Mechanism | LMPF Required? | Pros | Cons |

| Thermal Bonding (LMPF) | Melting and resolidification | Yes | Clean, strong, scalable | Requires thermal control |

| Chemical Bonding | Resin application and curing | No | Easy to implement | Potential VOC emissions |

| Mechanical Bonding | Needle punching or hydroentangling | No | High strength and texture | May damage the fiber structure |

| Adhesive Bonding | Hot melt or liquid glues | No | Fast and strong bonds | Adds foreign material |

Challenges and Considerations in LMPF Bonding

Despite its advantages, thermal bonding with LMPF comes with a few considerations:

- Heat Sensitivity of Additives: Colorants or functional additives must be stable at bonding temperatures.

- Fiber Distribution: Non-uniform mixing of LMPF can lead to weak zones.

- Processing Complexity: Requires fine control of temperature, pressure, and time.

- Cost of LMPF: Generally higher than standard PET fibers, affecting overall cost balance.

To achieve the ideal balance between performance and economy, manufacturers must improve their fiber formulas and process parameters.

Thermal bonding with Low-Melt Polyester Fiber (LMPF) strengthens nonwoven textiles by fusing fibers without sacrificing softness, breathability, or sustainability.