Polyester Staple Fiber in Automotive Soundproofing: A Complete Guide

Automotive noise, vibration, and harshness (NVH) remain key challenges in vehicle design. To meet growing demand for quieter, more comfortable

Home » Uncategorized

Automotive noise, vibration, and harshness (NVH) remain key challenges in vehicle design. To meet growing demand for quieter, more comfortable

Polyester staple fiber (PSF) has emerged as one of the most widely used and versatile materials in the furniture and

Polyester staple fiber (PSF) serves a wide range of end uses, from textiles and nonwovens to home furnishings, automotive interiors,

Polyester is widely utilized in garments, household textiles, industrial materials, and nonwoven fabrics. It comes in a variety of forms,

Recycled polyester staple fiber (rPSF) is the workhorse fiber made from post-consumer PET bottles and post-industrial polyester waste. It feeds

Quality control (QC) is crucial in polystyrene fiber (PSF) production. As a professional PSF manufacturer, Boporea adheres to strict quality

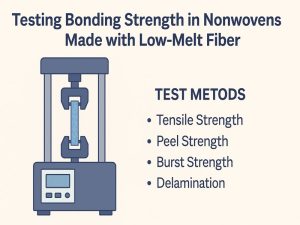

Low-melt polyester fibers are key to thermally bonded nonwovens, melting at 110–180°C to act as internal adhesives. Used in filters,

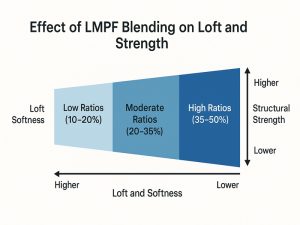

Balancing softness, durability, and resilience is key in nonwovens. Low-Melt Polyester Fiber (LMPF) offers an effective solution by enabling thermal

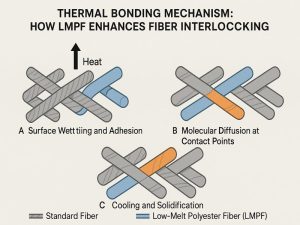

Thermal bonding is a key method in textile and nonwoven manufacturing, offering strength, flexibility, and eco-efficiency. Low-Melt Polyester Fiber (LMPF),

In textiles, visual appeal matters as much as performance—especially outdoors or under UV. Virgin Dope Dyed Polyester Staple Fiber (PSF)