Balancing softness, durability, and resilience is key in nonwovens. Low-Melt Polyester Fiber (LMPF) offers an effective solution by enabling thermal bonding without adhesives or stitching. However, its performance depends heavily on the blending ratio with standard fibers. This article explores how different LMPF ratios impact product properties and provides practical tips for optimizing formulations.

Understanding LMPF and Its Role in Thermal Bonding

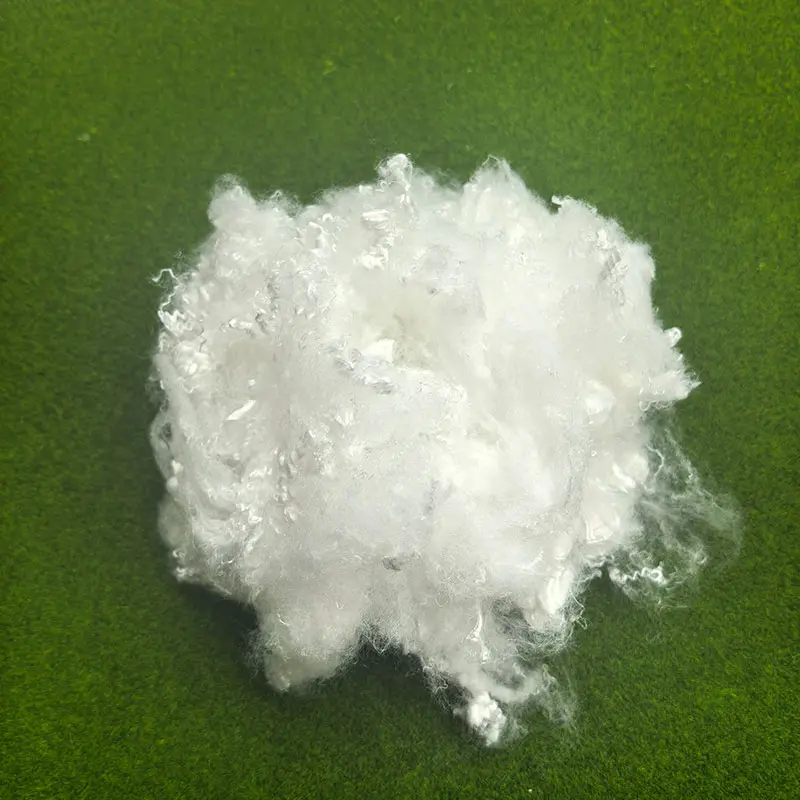

Low-Melt Polyester Fiber is a bi-component or mono-component fiber engineered to melt at lower temperatures (typically 110–180°C), much lower than standard polyester. When heat is applied, the LMPF softens or melts and then re-solidifies upon cooling, bonding adjacent fibers together. This creates a web or matrix that provides structural integrity without compromising softness or adding unnecessary weight.

Because it can be processed without additional adhesives, LMPF is considered an eco-friendly and clean bonding option in various nonwoven products, including:

- Insulation panels

- Automotive interiors

- Mattress padding

- Filter media

- Hygiene products

- Sound-absorbing materials

The key to maximizing LMPF’s benefits lies in its blending ratio with other fibers, such as PET, cotton, wool, or viscose.

What Is a Blending Ratio?

The blending ratio refers to the proportion of LMPF to conventional or functional fibers in a nonwoven fabric. For example, a 20:80 LMPF-to-PET ratio means that 20% of the fiber content is LMPF, and the remaining 80% is standard polyester. Adjusting this ratio allows manufacturers to tune specific properties such as:

- Loft (thickness and bulkiness)

- Tensile strength

- Resilience and recovery

- Surface smoothness

- Porosity and air permeability

The optimal blend depends largely on the desired final application, bonding method (e.g., hot air, calender, or infrared), and mechanical processing.

How LMPF Blending Affects Loft

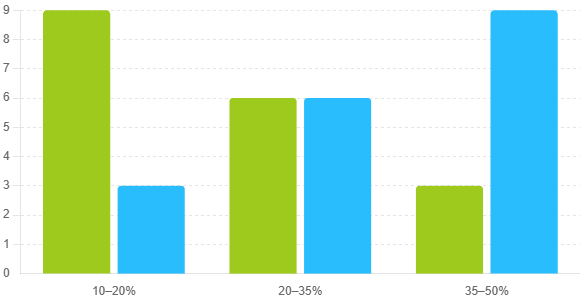

Low Ratios (10–20%)

In applications where high loft and softness are prioritized, such as bedding, insulation, or acoustic panels, a lower percentage of LMPF is typically used. This ensures minimal fiber melting, which allows the structure to maintain a fluffy, springy texture.

Pros:

- Maximizes air volume and thermal insulation

- Maintains flexibility and hand feel

- Reduces stiffness

Cons:

- Lower bonding strength

- Reduced shape retention under pressure

- May require more careful heat control to avoid delamination

Recommended Applications:

- Quilted padding

- Sound-absorbing panels

- Lightweight insulation

Moderate Ratios (20–35%)

This range offers a balanced performance between loft and structural integrity. It’s suitable for products that need both comfort and stability, such as mattress pads, sofa cushions, or automotive seat backing.

Pros:

- Good strength-to-weight ratio

- Moderate loft with improved resilience

- Enhanced bonding uniformity

Cons:

- Slightly reduced softness compared to lower blends

- Moderate thermal conductivity

Recommended Applications:

- Upholstery

- Thermal pads

- Composite insulation

High Ratios (35–50%)

When dimensional stability and strength are more critical than bulk, higher LMPF ratios are employed. These blends yield dense, firm, and compact materials that can endure repeated stress and mechanical load.

Pros:

- Strong inter-fiber bonding

- High durability and shape retention

- Improved washability and wear resistance

Cons:

- Lower loft and flexibility

- May feel rigid or less breathable

Recommended Applications:

- Automotive trunk liners

- Protective padding

- Packaging reinforcements

Effect on Mechanical Strength

Increasing LMPF content generally enhances tensile strength, tear resistance, and structural stability. The molten LMPF forms “bonding points” at fiber junctions, locking the fibers into a more unified matrix. This allows the nonwoven web to withstand stretching, compression, and repeated use.

However, excessive LMPF may lead to over-bonding, making the material too stiff or brittle. In some cases, such as hygiene products or filters, over-bonding can also block pores and reduce breathability.

Tip: A good compromise between strength and softness can often be achieved by using bi-component LMPF (with a low-melt sheath and a high-melt core), which enhances bonding without full fiber collapse.

Influence on Thermal Bonding Techniques

The bonding method used also plays a role in determining the ideal blending ratio:

| Bonding Method | Recommended LMPF Ratio | Notes |

| Hot Air Bonding | 15–30% | Preserves loft; suitable for thermal insulation |

| Calender Bonding | 30–50% | Allows surface smoothing; more suited for dense products |

| Infrared Bonding | 20–35% | Provides uniform bonding; ideal for composite layers |

| Oven Bonding | 20–40% | Well-suited for thick webs and multilayer laminates |

Proper temperature control is essential. Overheating may degrade the fiber matrix, while insufficient heat fails to activate LMPF bonding.

Environmental and Cost Considerations

While LMPF enhances product quality, it also impacts material costs. Since LMPF is a specialized thermoplastic fiber, its price per kilogram is usually higher than standard polyester or cotton.

Optimizing LMPF ratios helps control production costs while meeting performance goals. In eco-sensitive applications, manufacturers also prefer:

- Recycled PET-based LMPF

- Bio-based or biodegradable alternatives (e.g., PLA-based low-melt fibers)

- Blends that reduce synthetic content without sacrificing performance

Practical Guidelines for Manufacturers

Identify the End Use First

Is the product meant for comfort, protection, filtration, or acoustic dampening? Define the performance expectations—loft, softness, durability, or thermal resistance.

Run Lab-Scale Trials

Use pilot-scale blending and bonding tests to validate the impact of different LMPF ratios. Monitor loft recovery, tensile strength, and air permeability.

Adjust for Layering

Multi-layered nonwovens can use different LMPF ratios in each layer to achieve hybrid functionality. For example:

- Outer layer: high strength with 40% LMPF

- Middle layer: high loft with 15% LMPF

- Inner layer: skin contact comfort with 10–15% LMPF

Calibrate Heat and Pressure

Fine-tuning temperature and bonding pressure according to the LMPF ratio ensures consistent bonding and avoids fiber degradation.

Consider Alternative Fiber Blends

Blending LMPF with viscose, cotton, or specialty synthetic fibers can broaden performance options—but may require different heat profiles.

Case Study: Acoustic Panels

A manufacturer of acoustic wall panels approached us with a customer who wanted to improve sound absorption without sacrificing panel stiffness. They tested three LMPF mixes:

- 10% LMPF: Excellent bulk, but poor dimensional stability

- 25% LMPF: Balanced sound absorption and compressive strength

- 40% LMPF: High stiffness, but significantly reduced sound insulation

Final choice: 25% LMPF with hot air bonding, which resulted in very high customer satisfaction due to optimized strength, thickness, and sound insulation.

LMPF blending ratios are vital for optimizing loft, strength, and usability in nonwovens. Lower ratios enhance softness, while higher ones add durability. Balanced formulations tailored to product needs and bonding methods yield the best results. With careful testing and process tuning, manufacturers can maximize LMPF’s performance to meet modern functional and environmental demands.